Screw Machine Services

Many technologies, one standard: on-time quality

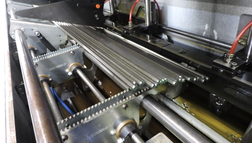

Our custom screw machining services are bolstered by our extensive Cox machine library and general breadth of screw machining technology. Few can match Cox in adherence to exacting specifications, or in the re-creation of complex geometries for high volume production of all types of specialized material parts.

Our Screw Machine Services Equipment

- CNC Swiss Turn by Tsugami— 24 machines

- CNC Swiss Turn by Tornos— 49 machines

- CNC Swiss Tornos Nano (4mm & 7mm)— 5 machines

- CNC Mill Turn Centers— 6 machines

- Multi Spindle Cam Automatics— 19 machines

- Tornos Precision Multi Spindle Automatics—11 machines

- Large Diameter 32mm BO machines by Tsugami— 4 machines

- Tool Room & Support Equipment

- Quality & Inspection Equipment

Medium & Short-Run Screw Machine Projects

Cox offers and is capable of producing both medium and short-run projects when providing our screw machining services. Cox has supplied the industry's leading screw machining services for more than six decades in a variety of materials for a wide range of applications.

Reliability in Manufacturing

While leading-edge technology is essential, it is only a tool for achieving the same goal we’ve pursued single-mindedly for 65+ years: to perform so reliably that customers confidently choose Cox as their preferred supplier. Customers trust Cox's expertise to spot manufacturability challenges and offer solutions that avoid bottlenecks. Suggesting optimum design for manufacturability can fine-tune an existing component to boost production speed and cut unit cost. Cox is a logistically ideal source for screw & swiss machining services tasks in the U.S. and Mexico.

Certifications & Quality Machining

Cox Manufacturing meets or exceeds the quality standards of the world's most demanding industries with our state-of-the-art equipment and trained professionals. A few of them include:

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process FMEA for automotive customers

- Skilled in KanBan and other customer driven quality and inventory management systems

- ITAR Registered

Interested in a career at Cox or ready to submit a resume?

To view any open positions or submit a resume, please click here!